Case Study 2 : Inventory Liquidation

Client Background :

The client operates 21+ manufacturing plants across India in the Breweries and Distilleries industry having turn over around 19,000cr. Their supply chain ecosystem includes raw materials, packaging components, engineering spares, and plant-critical consumables.

Over years of decentralized procurement and rapid expansion, the Material Master and Inventory Database became inconsistent, resulting in excess stock, duplicate item records, non-moving materials, and dead inventory accumulation—directly impacting working capital and operational agility.

![]()

Challenges & Business-Critical Data Issues :

The client encountered multiple operational and financial bottlenecks:

-

Difficulty in performing inventory liquidation decisions due to lack of trust between inter-plant stores

-

Dead inventory stock pile-up worth crores, untraceable due to poor descriptions

-

Non-moving materials not flagged or governed in Store operations & in SAP

-

No visibility into obsolete stock vs. active plant consumables

-

Duplicate material codes preventing accurate stock analysis

-

Missing technical attributes in material descriptions such as OEM, MPN & their correlation

-

Incorrect SAP Material Group & Type classification

-

Lack of data governance

![]()

W2W Solution :

Implemented a structured and scalable Inventory Optimization solution to restructure, enrich, validate, and rationalize material master data & stock, enabling accurate identification of dead and non-moving inventory for liquidation.

Transformation Framework

|

Project Stage |

Key Activities |

|

Pre-analysis |

In depth analysis of master data & plant stores to identify the root causes |

|

Physical Verification |

On-site physical verification of materials to validate existence, condition, and usability at each plant Technical attributes verification of spares with SAP descriptions to identify the mismatches and to enrich the existing SAP material descriptions Capture of actual material image for web-based platform |

|

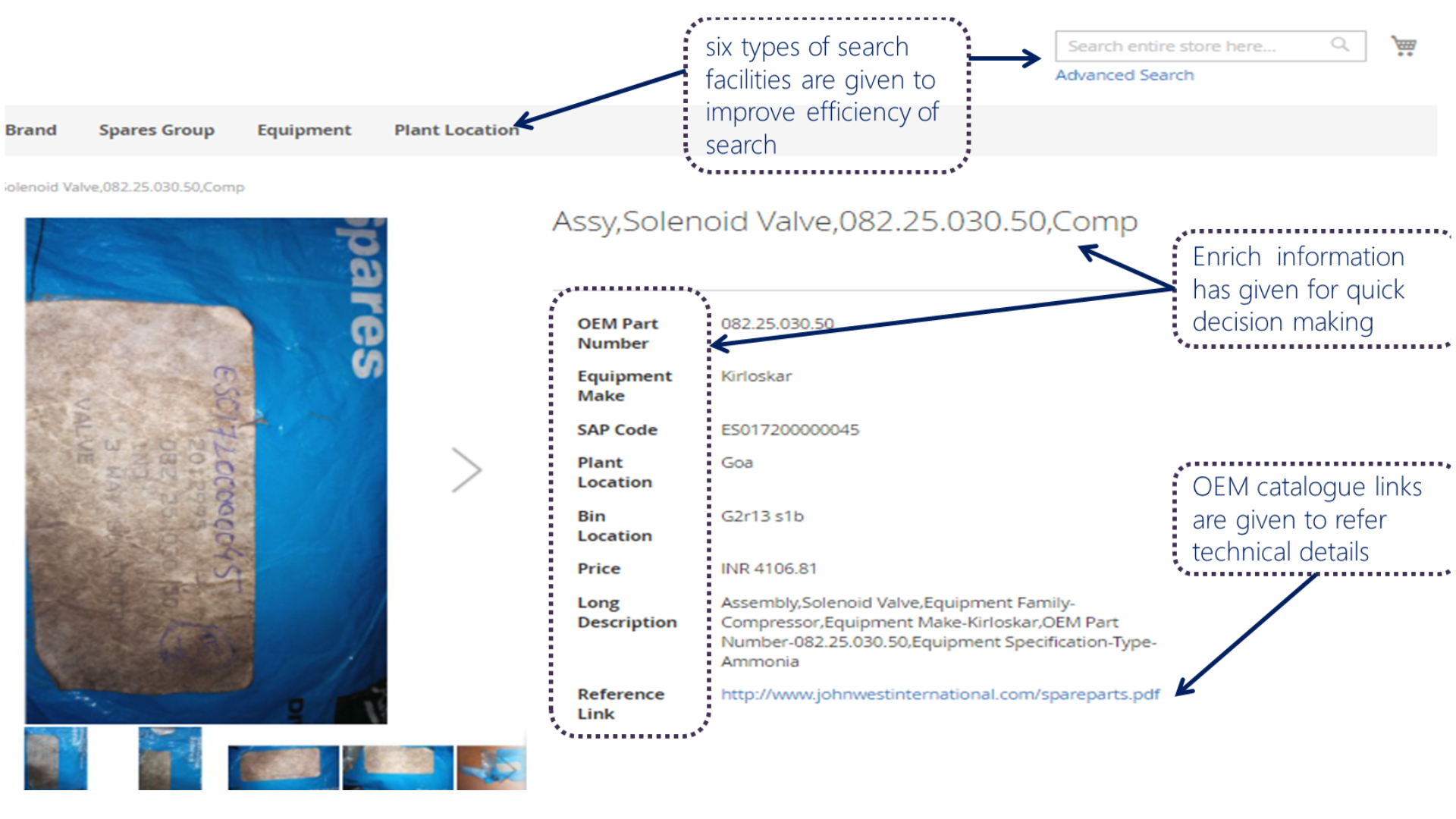

Inter-Plant Collaboration Website |

An innovative, customized website Platform for smooth inter plant communication, material data exchange to build the trust between inter-plant stores by:

|

|

Inventory Intelligence |

Material Flagging based on Non-moving, Slow-moving, dead & obsolete inventory for liquidation insights |

|

Data Cleansing |

Duplicate detection, phase-out spare identification (equipment/machine and technology), Conversion of OEM spares into standard spares |

|

Data Standardization |

Normalization of Category, OEM/MPN structuring, UoM, Size formats, Abbreviations, Tag numbers, Text Separator. Design and implement string consistency based on customer requirements and MRO category standards |

|

Data Enrichment |

Technical Attribute such as OEM/MPN/Size/UoM etc., tags & drawing numbers, OEM equipment details. Implementation of attribute labels & value combination for long descriptions. |

|

Data Validation |

Technical Attributes verification from catalogues/drawings & through physical verification |

Results & Business Impact :

Results & Business Impact :

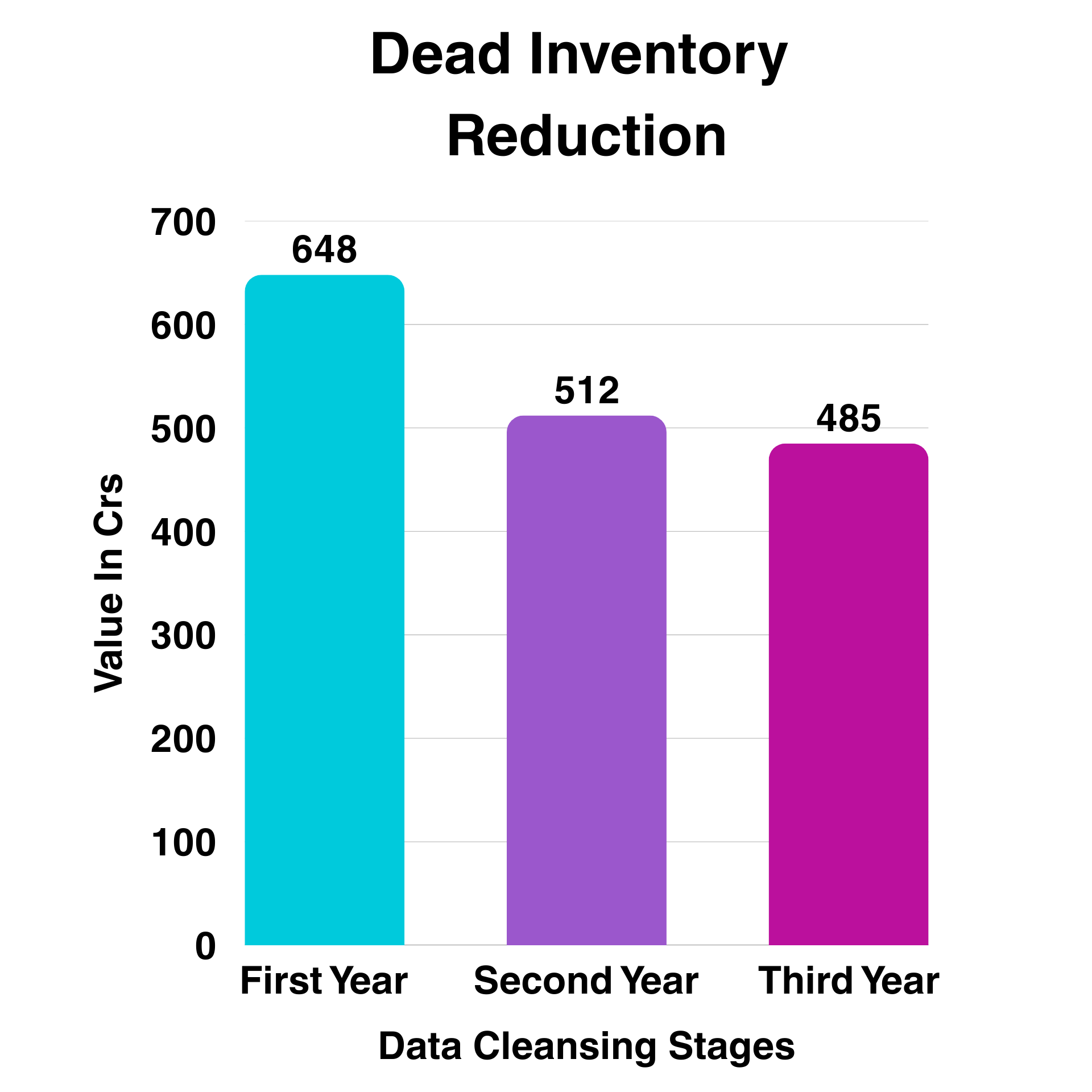

1. Inventory & Working Capital Optimization

-

Inventory volume reduced from 648 cr to 485 cr (approx. 25% reduction) due to new concept implementation of web-based platform

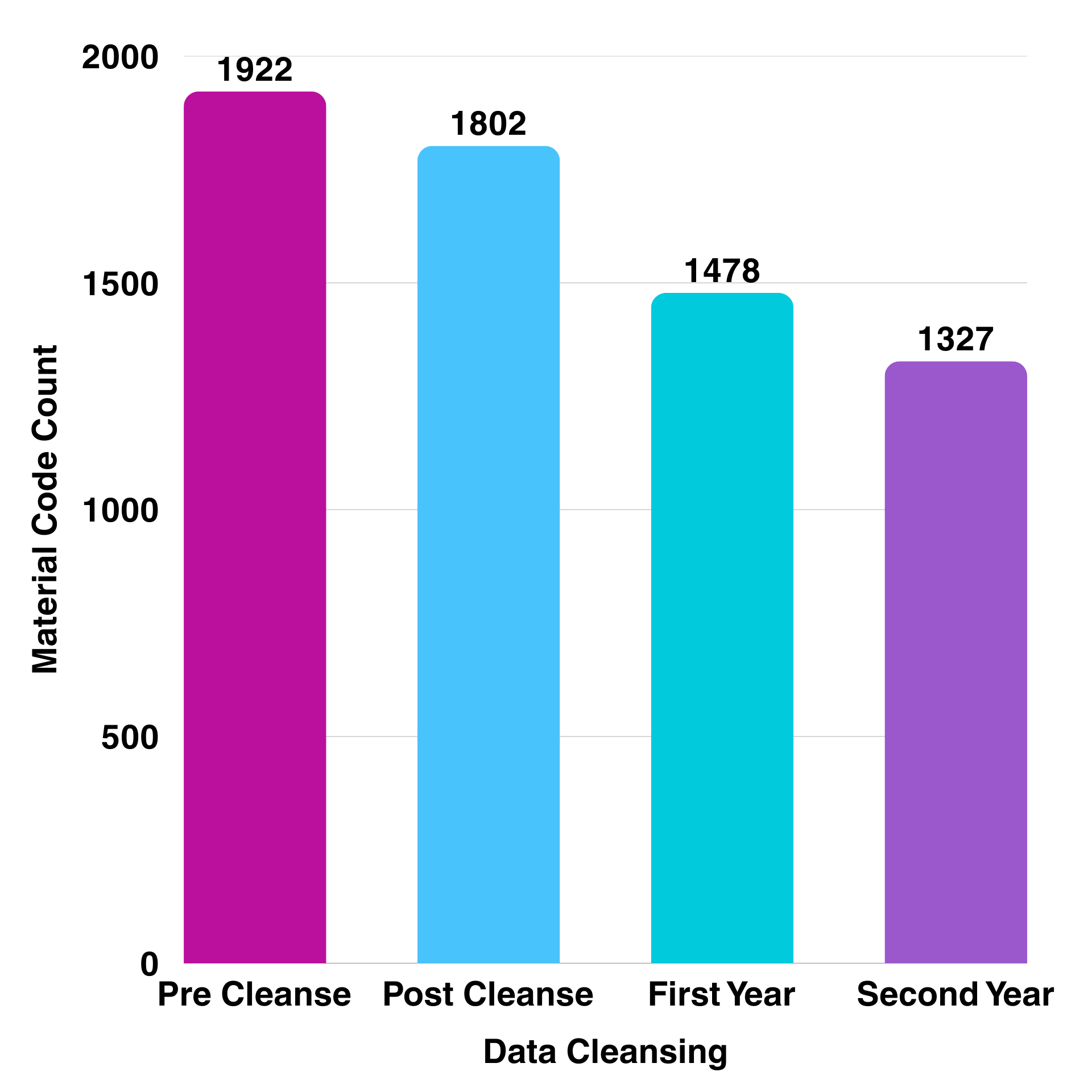

2. Quality Improvement in Material Master Data

-

30~35% technical attributes mismatch found in SAP material descriptions because action of physical verification

-

31% reduction in material codes i.e. 1922 SKU’s reduced to 1327 SKU’s after data cleansing/enrichment/validation

-

100% accuracy achieved for Data Standardization

-

85% accuracy achieved for Data Enrichment & Data Validation

3. Long-Term Reliability & Governance for Non-Moving & Dead Inventory

-

Master data now functions as a trusted source for inventory liquidation strategy

Key Outcomes Delivered :

-

Centralized Non-Moving & Dead Inventory Governance Model

-

Structured and enriched Material Master Database

-

Reliable technical data & stock information for inventory liquidation decisions

-

Improved trust level between stores across 21+ plants

-

Faster engineering spares search which helps maintenance department decisions

-

Working capital optimization for long-term benefits

Conclusion :

W2W’s Inventory Optimization & Material Master Solution empowered the client to convert unstructured master data into actionable intelligence, enabling confident identification of non-moving and dead inventory, accelerating liquidation decisions, and recovering trapped working capital—while establishing a future-ready, compliant, and duplicate-free SAP material governance system.